FAQ: How to protect plastic products against UV radiation

Italmaster is also the right place for appropriate advice and support. That's why we made an informative video explaining the use of UV stabilizer in masterbatches.

We let our CEO Michel Staelens explain this to you. Be sure to check our video on Youtube here!

How do you protect plastics against UV radiation?

As a manufacturer of masterbatch, we regularly receive questions about the protection of plastics against UV radiation. We hope this gives you some clarification.

A masterbatch is the concentrate of color pigments and additives. It is used to color plastics or synthetic fibres, or in certain cases to add mechanical and thermal properties. The color pigments and additives are encapsulated in a plastic carrier by an extrusion process, then cooled and cut into granulate grains.

These granulate granules are the semi-finished product, which our customer - the plastic processor, injection molder or extruder - in turn further mixes with its raw material to ultimately produce a finished plastic product.

- A monobatch only contains color pigments.

- A combi batch unites color pigments and additives.

A frequently used additive is the UV stabilizer, which protects the polymer - say the raw material from which the plastic product consists - against degradation by UV radiation.

Exposure to sunlight has a negative effect on the lifespan of plastics: UV radiation breaks down the chemical bonds of the polymer. This process results in color fading, cracking and loss of mechanical properties.

During the injection molding or extrusion process, a UV stabilizer can be added separately to the raw material/polymer, or it may be preferred to already provide the UV stabilizer in the build-up: the formulation of the masterbatch.

By adding a UV stabilizer to the raw material/polymer you get a certain degree of protection. This should be determined in function of the expected life of the plastic product and depends on the amount, but also on the type of UV stabilizer.

The color of the plastic product - applied by mixing the masterbatch - can be protected against UV radiation by selecting pigments with high light fastness and high weather fastness.

If the color pigment in the masterbatch has a low light or weather fastness, the color of the plastic product will also disappear in the long run: even when high levels of UV stabilizer are added, which will ultimately only protect the raw material polymer.

UV stabilizers therefore serve to protect the polymerand they are completely independent of the protection of the color pigments in the masterbatch.

Only a combination of high-quality color pigments with a UV stabilizer is therefore effective if one wants to protect plastic outdoor applications in a correct way against UV radiation.

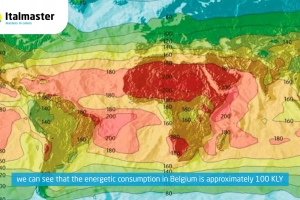

The exposure to sunlight in duration and intensity determines the energy consumption. The energy consumption of UV is expressed by the unit Kilo Langley (KLY) and is geographically determined. For example, there is more energy consumption in Southern Europe than in Northern Europe. The consumption per year per region is shown on the KLY World Map.

A concrete example provides clarification on how the amount of UV stabilizer is ultimately determined.

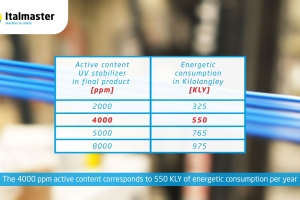

We also express the content of UV stabilizer in the plastic product in Parts Per Million = ppm. The images show a diagram with the KLY protection depending on the amount of the specific UV stabilizer that we often use at Italmaster.

If we provide 50% UV stabilizer with a 40% filling degree in a masterbatch, and this masterbatch is mixed at a dosage percentage of 2%, this ultimately results in a level of 4000 ppm UV protection in the plastic product.

50% x 40% x 2% = 4000ppm

The 4000 ppm active content corresponds to 550 KLY energy consumption per year.

If we now include the KLY world map, we can see that the energy consumption in Belgium is about 100 KLY. In our example, the plastic product is theoretically protected against UV radiation for 5.5 years.

We hope we have taught you something about the protection of plastic products against UV radiation.

It is important to remember that both the polymer and the color pigments must be protected.

We are very happy to help you with more explanation, information and support with all your future projects!

Let’s start developing together! Click on this link to send us your lab request.

Italmaster Belgium NV is your flexible partner for the development, production and sales of masterbatches, monopigments & additives. Contact us for the development, production and flexible delivery of your masterbatch in Belgium, the Netherlands, France and other countries of the European Union.

Published on: 05/02/2021