The 7 most important aspects of color consistency in masterbatch

The importance of color consistency in the production process is more than just a technical detail: it is a crucial element that is reflected in various aspects of the masterbatch and plastics industry. The importance of maintaining accurate color formulations cannot be overstated as it impacts brand integrity, customer satisfaction and operational excellence. In this article, we delve into the seven crucial factors that highlight the importance of color consistency in masterbatch production.

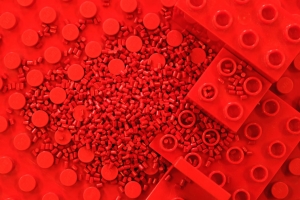

We were inspired by a well-known example: toys. For this article we specifically use plastic building blocks as an example. By exploring how color precision plays a crucial role in the world of this product, we discover the reasons why maintaining consistent colors in masterbatch is not only a technical necessity, but also a strategic imperative.

Discover the 7 reasons why color consistency in masterbatch is crucial for your final product :

1. Brand identity : Consistent colors are essential for maintaining a brand's identity. Brands that offer plastic building blocks usually have a clear color palette, and any deviation from this can affect the brand recognition they have built up over the years.

2. Aesthetics : Building block toy sets often have complex designs with the colors playing an important role in the overall aesthetic of the final product. Inconsistent colors can be distracting and affect the visual appeal of the toy set.

3. Customer Expectations : Customers expect a certain level of quality and uniformity in their products. Inconsistent colors in the different building blocks could lead to dissatisfaction among consumers and could be considered a defect.

4. Interchangeability : One of the most important features of building block sets is their interchangeability. The pieces from different sets and different times must fit together seamlessly. Consistent color ensures that newer batches of building blocks match the color of older ones, maintaining the sets' compatibility and play value over time.

5. Quality Control : Ensuring color consistency is part of the quality control process. Toy manufacturers, like many other companies, have strict quality standards. Inconsistent colors can be an indication of a problem in the production process.

6. Production Efficiency : Maintaining color consistency in masterbatch helps in the production process. If the color is consistent, this reduces the chance of production errors, scrap and the need for rework. This in turn increases production efficiency and reduces waste.

7. Consumer trust : Consistency in color contributes to the overall trust consumers place in the brand. In this example, if the toy brand consistently delivers products with the expected color quality, consumers are more likely to trust the brand and continue making purchases.

In summary, we can conclude that color consistency is not just an aesthetic concern for products such as plastic building blocks; it is an integral part of the brand, product quality, customer satisfaction and the overall success of the company.

Color consistency in our masterbatch

Color consistency in masterbatch is of utmost importance at Italmaster, where the commitment to maintaining high standards is a fundamental aspect of the production process. This commitment to color precision is integral to several facets of our company's operations, ensuring a product that meets customer expectations at all times.

Our team of professional colorists selects the right pigments and develops the masterbatch that meets all your requirements. After the development process, you can request a sample so that you can test the developed masterbatch in your own production process. With your approval, the sample becomes the 'master standard', the reference for all further productions.

Would you like more technical support or other information? Please do not hesitate to contact us without obligation by email: info@italmaster.be or by telephone: +32(0)9/3808754.

We are happy to develop a masterbatch tailored to your wishes and requirements !

Italmaster Belgium NV is your flexible partner for the development, production and sales of masterbatches, monopigments & additives. Contact us for the development, production and flexible delivery of your masterbatch in Belgium, the Netherlands, France and other countries of the European Union.

Published on: 30/01/2024